🎉 June Kickoff Challenge: Win a $500 Gift Card! 🎉

Summer is here, and we’re celebrating with an exciting community giveaway. Here’s your chance to win a $500 gift card of your choice (Amazon, Home Depot, Bass Pro Shop - you name it)!

How to Enter:

- Sign Up for the Community: If you haven’t already, sign up for the MaintainX community.

- Share Your Best Practices, Tips, or Tricks: Post a detailed example of a workflow, tip, or trick that has helped your team using MaintainX. Whether it’s a process you’ve digitized or a clever trick you’ve discovered, we want to hear about it! Don’t be nervous, what may sound simple to your team, could be a major insight for others!

- Engage: Don’t forget to like and comment on other posts to support your fellow community members.

Submission Guidelines:

- Title: Give your workflow, tip, or trick a catchy title.

- Description: Provide a clear and concise description of your best practice, tip, or trick. Explain how it helps your team and why it’s effective.

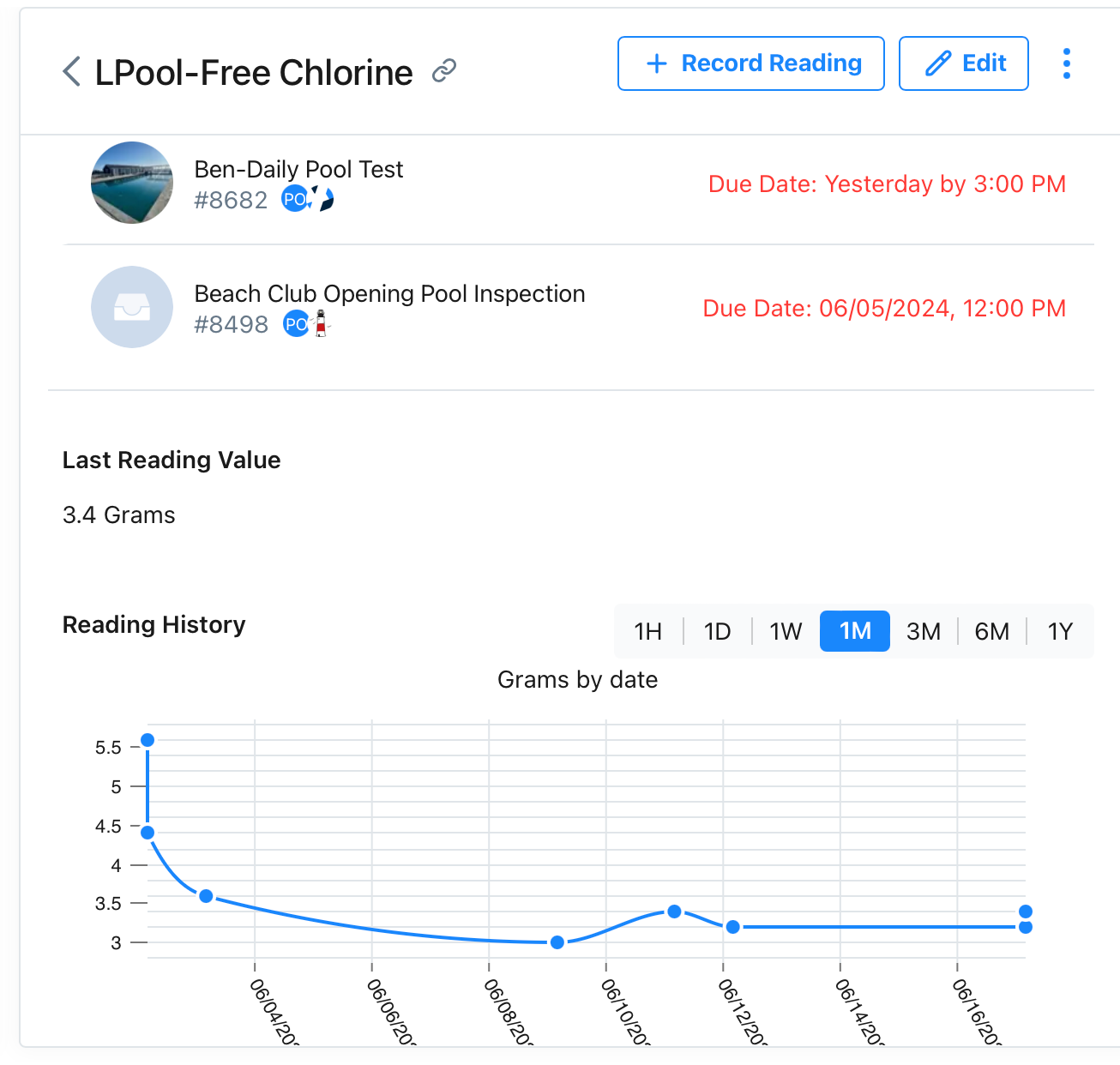

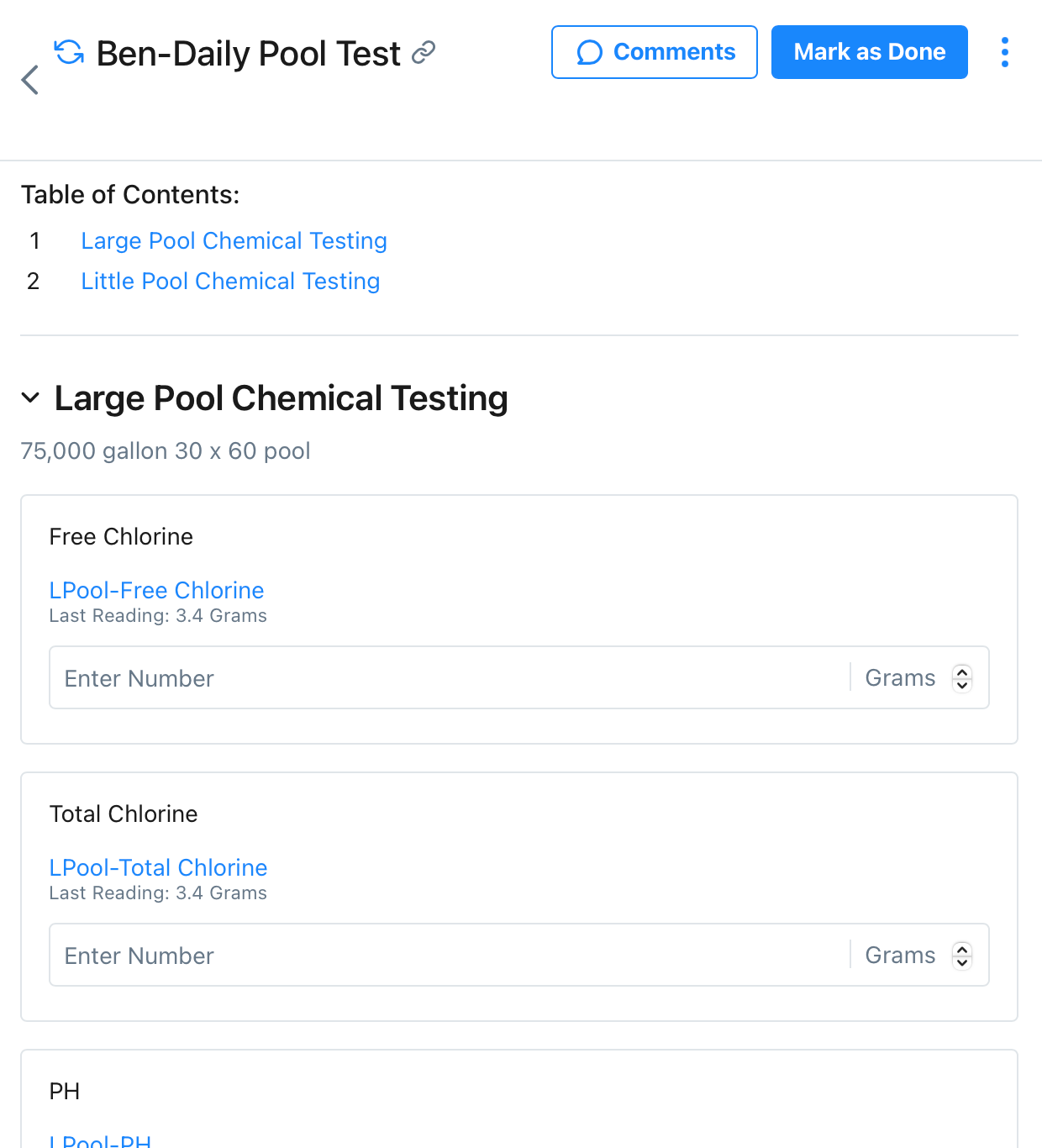

- Visuals: Include screenshots, photos, or videos to illustrate your example.

Example Post:

Title: Streamlining Equipment Inspections with MaintainX

Description: Our team has digitized our equipment inspection process using MaintainX. We created a custom checklist for daily inspections, which has significantly reduced errors and improved compliance. Here’s how we did it…

Visuals: [Include screenshots of the checklist, photos of the inspection process, or a short video walkthrough]

Prize: The best workflow, tip, or trick shared by June 30th will win a $500 gift card of your choice (including option to donate to charity of your choice)! 🎁 The post with the most likes in this thread will win the prize!

Winner Announcement: We will announce the winner on July 1st right here in the community. Stay tuned and get ready to celebrate!

Join the challenge today and let’s make the MaintainX community a place where everyone can learn and grow together. We can’t wait to see your amazing workflows, tips, and tricks!

Good luck! 🚀

Nick and the MaintainX Community Team